Fire is one of the biggest risks in closed structures. While some of the deaths and injuries in fires are caused by high heat, another important part is injured or died due to carbon monoxide, which is a toxic gas.For this reason, it is very important to correctly position the clean air and smoke evacuation shafts and jet fans that constitute the main and backup ventilation systems during fire simulations and fire in closed structures. Ventilation systems should be able to ventilate in a way that allows people to escape and should be able to isolate the fire. In addition, in order to prepare escape plans and routes, it should be known which areas have dangerous levels of toxic gas concentration and which areas are heated in a way that does not allow human escape.

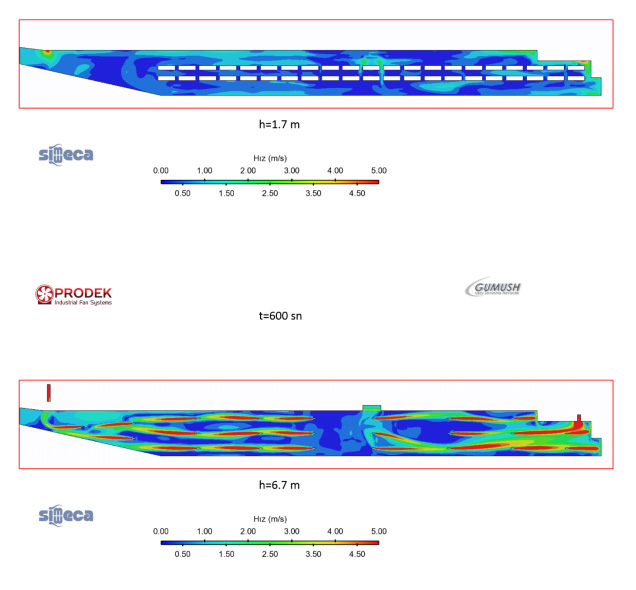

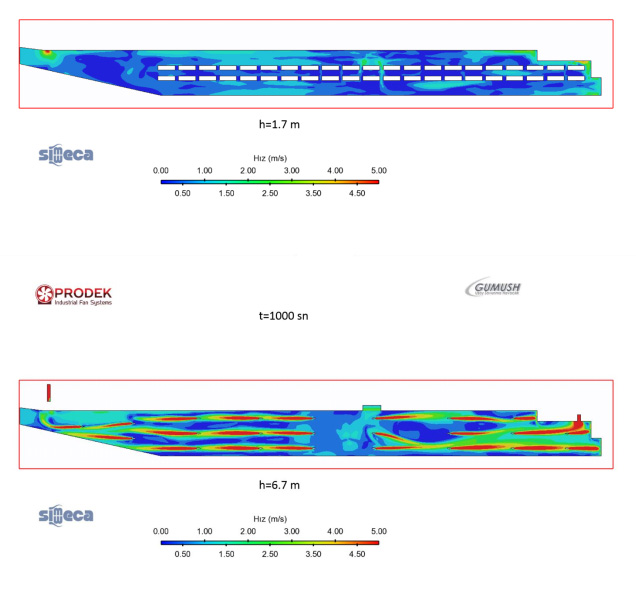

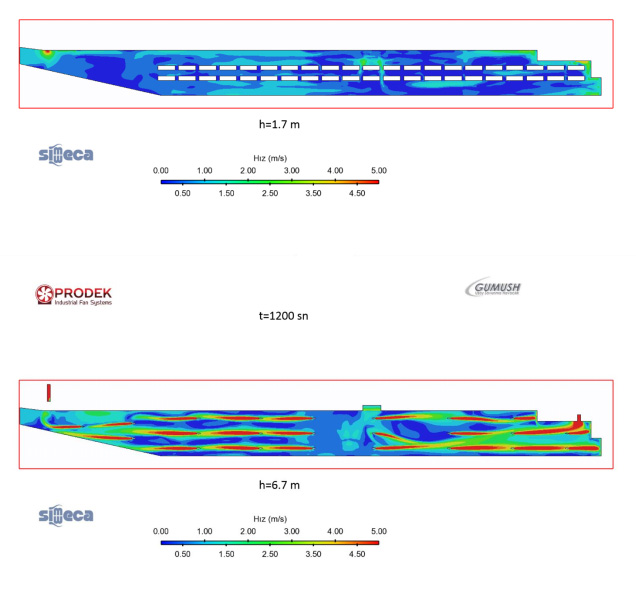

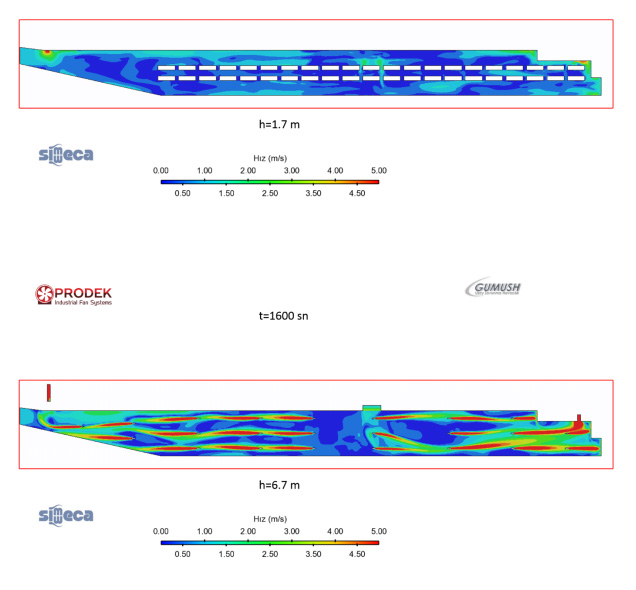

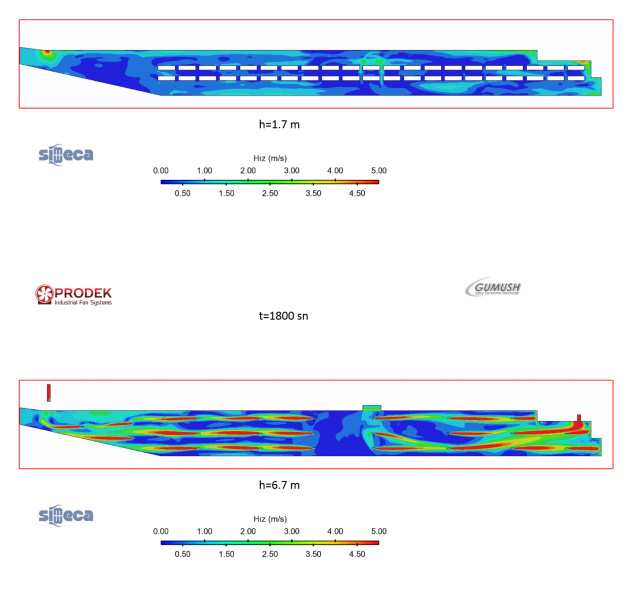

Computational Fluid Dynamics (HAD-CFD) is a branch of fluid dynamics and numerical methods and algorithms are used to solve and analyze fluid problems in designs. Computers are used to realize these solutions and simulate interactions between liquids and gases using boundary conditions defined by surfaces. Better solutions can be produced thanks to high-speed supercomputers. However, thanks to technological developments, CFD can be realized by using reasonable computer resources. Thanks to the developments on the software side, complex and complex simulations (eg turbulent flows, polyphase flows, supersonic flows) can be easily modeled.

The fire and smoke performance of the main and backup ventilation systems, whose design phase has been terminated with the commissioning of the system, is carried out with smoke generator tests. Headless ventilation systems, the performance of which is observed as a result of the test, causes cost and time loss. The use of computational fluid dynamics (HAD) in the field of fire safety engineering can be achieved in a realistic amount with a non-reactive flow solution in which the fire is defined with the correct properties, the component location of the ventilation systems at the design stage, the fire commissioning plans, the performance of the system and its components according to the BS7346-7 standard and American NIOSH norms. and can provide a realistic amount of accurate information about the adequacy of the system.

The fire phenomenon is a flow phenomenon triggered by the combustion (deflation) occurring at subsonic speeds numerically and under the effect of buoyancy (under the influence of gravity) in terms of its basic characteristics.

Fire-smoke exhaust and fire rescue systems, which are used to assist human escape, generally include fresh air shafts and industrial type fresh air fans placed inside, smoke exhaust shafts and hot smoke resistant smoke exhaust fans placed inside, if they are made through the exhaust duct installation from the environment, the duct system and all electro-mechanical components within its body, if the jetfan system, which is another auxiliary system to the exhaust, is used, the jet fans, the smoke windows in the windows of the exhaust and fresh air shafts opening to the environment, the fire windows used to confine the fire flame to a certain area, the fire extinguisher with irrigation following the onset of the fire. It includes the sprinkler system and installation, as well as the sensors (sensor), electrical panel and power wiring and control panels within the control system that activate all fans, windows and sprinkler system components. The smoke exhaust system with jet fan, which is also referred to as “Impulse Ventilation” in the sources, must meet some basic features specified in the British BS7346-7 standard, which is the source of the Turkish Fire Standard.

If given with the item numbers in the BS7346-7:2006 standard:

9.1.1 – If a fire is detected, the main exhaust fans should be activated immediately to provide the required exhaust flow rate.

9.1.2 – After an appropriate delay period (the time from the start of the fire to the moment the jet fans are activated), the jet fans should take action to efficiently direct the smoke to the exhaust points. The delay period should be in accordance with the design period for the escape of people.

9.1.4 – The number of air changes in the parking garage should be at least 10 air changes per hour.

While designing the fire rescue system, the closed volume is considered as consisting of independent and unrelated – as if – discrete volumes. This process is called zoning for smoke control. CFD plays a major redeeming role in understanding the time dependent behavior of fire. With the use of numerical methods in fire safety engineering, possible fire situations can be solved by computer simulation, the adequacy of escape times for people in the event of a fire, the capabilities of fire smoke exhaust systems can be investigated, and even more importantly, architectural design improvements and verifications for fire can be made.Fire is one of the biggest risks in closed structures. While some of the deaths and injuries in fires are caused by high heat, another important part is injured or died due to carbon monoxide, which is a toxic gas. For this reason, it is very important to correctly position the clean air and smoke evacuation shafts and jet fans that constitute the main and backup ventilation systems during fire simulations and fire in closed structures. Ventilation systems should be able to ventilate in a way that allows people to escape and should be able to isolate the fire. In addition, in order to prepare escape plans and routes, it should be known which areas have dangerous levels of toxic gas concentration and which areas are heated in a way that does not allow human escape.

Computational Fluid Dynamics (HAD-CFD) is a branch of fluid dynamics and numerical methods and algorithms are used to solve and analyze fluid problems in designs. Computers are used to realize these solutions and simulate interactions between liquids and gases using boundary conditions defined by surfaces. Better solutions can be produced thanks to high-speed supercomputers. However, thanks to technological developments, CFD can be realized by using reasonable computer resources. Thanks to the developments on the software side, complex and complex simulations (eg turbulent flows, polyphase flows, supersonic flows) can be easily modeled.

The fire and smoke performance of the main and backup ventilation systems, whose design phase has been terminated with the commissioning of the system, is carried out with smoke generator tests. Headless ventilation systems, the performance of which is observed as a result of the test, causes cost and time loss. The use of computational fluid dynamics (HAD) in the field of fire safety engineering can be achieved in a realistic amount with a non-reactive flow solution in which the fire is defined with the correct properties, the component location of the ventilation systems at the design stage, the fire commissioning plans, the performance of the system and its components according to the BS7346-7 standard and American NIOSH norms. and can provide a realistic amount of accurate information about the adequacy of the system.

The fire phenomenon is a flow phenomenon triggered by the combustion (deflation) occurring at subsonic speeds numerically and under the effect of buoyancy (under the influence of gravity) in terms of its basic characteristics.

Fire-smoke exhaust and fire rescue systems, which are used to assist human escape, generally include fresh air shafts and industrial type fresh air fans placed inside, smoke exhaust shafts and hot smoke resistant smoke exhaust fans placed inside, if they are made through the exhaust duct installation from the environment, the duct system and all electro-mechanical components within its body, if the jetfan system, which is another auxiliary system to the exhaust, is used, the jet fans, the smoke windows in the windows of the exhaust and fresh air shafts opening to the environment, the fire windows used to confine the fire flame to a certain area, the fire extinguisher with irrigation following the onset of the fire. It includes the sprinkler system and installation, as well as the sensors (sensor), electrical panel and power wiring and control panels within the control system that activate all fans, windows and sprinkler system components. The smoke exhaust system with jet fan, which is also referred to as “Impulse Ventilation” in the sources, must meet some basic features specified in the British BS7346-7 standard, which is the source of the Turkish Fire Standard.

If given with the item numbers in the BS7346-7:2006 standard:

9.1.1 – If a fire is detected, the main exhaust fans should be activated immediately to provide the required exhaust flow rate.

9.1.2 – After an appropriate delay period (the time from the start of the fire to the moment the jet fans are activated), the jet fans should take action to efficiently direct the smoke to the exhaust points. The delay period should be in accordance with the design period for the escape of people.

9.1.4 – The number of air changes in the parking garage should be at least 10 air changes per hour.

While designing the fire rescue system, the closed volume is considered as consisting of independent and unrelated – as if – discrete volumes. This process is called zoning for smoke control.

CFD plays a major redeeming role in understanding the time dependent behavior of fire. With the use of numerical methods in fire safety engineering, possible fire situations can be solved by computer simulation, the adequacy of escape times for people in the event of a fire, the capabilities of fire smoke exhaust systems can be investigated, and even more importantly, architectural design improvements and verifications for fire can be made.